Welcome to Lean Material Handling

Improve Your Material Handling

Improve your Efficiency

Improve Your Safety

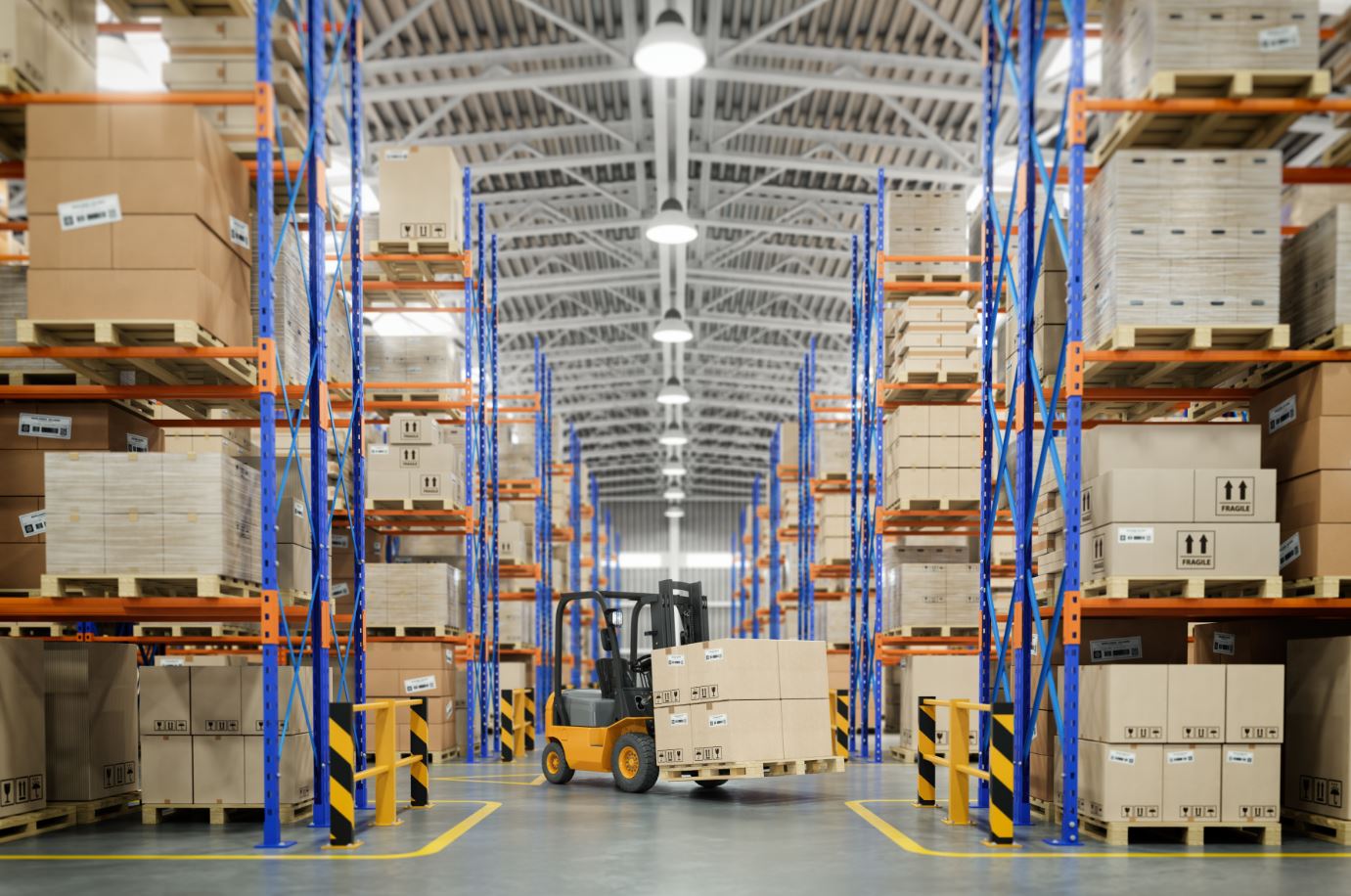

What is Lean Material Handling?

What is Lean Manufacturing?

Lean Manufacturing refers to the idea of adapting lean practices, principles and other tools to help improve the overall efficiency within a manufacturing environment. This was originally endorsed and developed through the Toyota Production System.

Read our Latest Posts

Lean more about Lean Material Handling Today

Lean Material Handling strives to provide information and guidance on how to improve your material handling.